A truly trouble – free sales and customer service experience

Customization of products as per client site requirements

Compact handheld portable analyzers

Provide Analyzers suitable for Hazardous Area

Spares and accessories availability guaranteed for years at reasonable price

A truly trouble – free sales and customer service experience

Customization of products as per client site requirements

Compact handheld portable analyzers

Provide Analyzers suitable for Hazardous Area

Spares and accessories availability guaranteed for years at reasonable price

A truly trouble – free sales and customer service experience

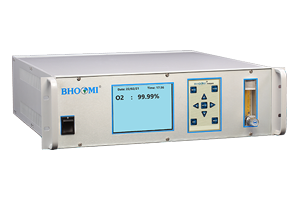

Gas And Liquid Analyzer Manufacturer and Supplier

About Us

Bhoomi Process Management Pvt. Ltd. (sister concern of Bhoomi Analyzers) is a leading manufacturer of Gas and Liquid Analytics for Process, Combustion, Emission and Renewable Energy applications. It was formed in June 2006 with vision of manufacturing world class products for process industries and related applications. We are an ISO 9001:2015 Certified Company with efficient Processes and Quality Management Systems. We demonstrate consistent quality and continual improvement in design, manufacturing and after sales services.

Years of Experience

Products & Solutions

Happy Clients

Projects Delivered

Our Products

Application

-

-

-

-

-

Biomedical & Common Waste Management Plant

Application - Biomedical & Waste Management Plant There are many ways of...

-

-

-

Our Projects

16 Nos. CEMS with 8 Nos. Pressurized Panel for Zone 2 Hazardous Area were supplied to EPC in Singapore.

8 Nos. CEMS Panel integrated with multiple technologies supplied to Petrochemical Industry.

15 Nos. CEMS Panels integrated with Remote Calibration Unit supplied to Steel Plant in India.

16 Nos. CEMS with 8 Nos. Pressurized Panel for Zone 2 Hazardous Area were supplied to Oil Refinery in India.

125 nos. Dust Monitor with Cross Duct Optical technology supplied to Rolling Mills Association in India.

15 Nos. CEMS Panels with integrated data communication supplied to Chemical Plant in India.

16 Nos. CEMS with 8 Nos. Pressurized Panel for Zone 2 Hazardous Area were supplied to EPC in Singapore.

8 Nos. CEMS Panel integrated with multiple technologies supplied to Petrochemical Industry.

15 Nos. CEMS Panels integrated with Remote Calibration Unit supplied to Steel Plant in India.

16 Nos. CEMS with 8 Nos. Pressurized Panel for Zone 2 Hazardous Area were supplied to Oil Refinery in India.

125 nos. Dust Monitor with Cross Duct Optical technology supplied to Rolling Mills Association in India.

15 Nos. CEMS Panels with integrated data communication supplied to Chemical Plant in India.

16 Nos. CEMS with 8 Nos. Pressurized Panel for Zone 2 Hazardous Area were supplied to EPC in Singapore.

8 Nos. CEMS Panel integrated with multiple technologies supplied to Petrochemical Industry.

15 Nos. CEMS Panels integrated with Remote Calibration Unit supplied to Steel Plant in India.

Our Blog

The impact of dust monitoring system on mining and cement industries

India’s rapid industrial growth has driven massive expansion in the mining and cement...

Importance of Online Water Analysers for ETP/STP Plants

Online water analysers are key for wastewater treatment. They help ETP (Effluent Treatment...

Role of Turbidity and Chlorine Analysers in Drinking Water Application

Poor water quality causes severe health complications, including gastrointestinal illnesses, chronic diseases, and...

Request a quote

Complete this form to receive a quote for our products of your choice. Our sales team will get in touch with you shortly.