Integrated Continuous Emission Monitoring System with SCU & Heated Probe & Sample Tubing

Integrated Continuous Emission Monitoring System with SCU & Heated Probe & Sample Tubing

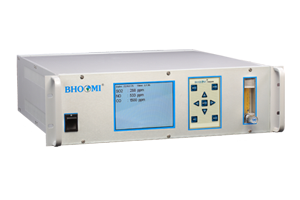

The Agasthya 2013 Series Continuous Emission Monitoring System BI 7000 is designed in compliance to emission norms to measure gases pollutants emitted by various process industries and to meet the needs of organizations requiring cost effective and reliable multiple gas analyzer solutions.

BI 7000 is TUV certified for CE mark & Performance as per EN15267 standard.

The technology employed are of maximum reliability and accuracy to ensure high degree of performance & long life.

BI 7000 is ideal solution to protect initial investment & can adapt to any process application with modular design & can house up to eight gas sensors with scalable ranges for each gas.

Manufactured for use in hostile or friendly environments the BI 7000 Continuous Emission Monitoring System maintains high levels of gas selectivity, all packed into a robust, attractive, industrial enclosure.

- Tried and tested technology with proven reliability

- Scalable ranges available for each gas

- 5.7” TFT Keypad Display

- The best price performance on the market – designed with user requirements foremost in mind

- Wide range of gas selectivity

- Unit programmable in ppm & mg/Nm³

- Isolated 4-20 mA analog output for each gas

- RS 485, MODBUS protocol

- High / Low Gas, low flow & other programmable events available

- Highly efficient automatic purge & drain system

- Inbuilt interface for Remote Calibration Unit

- Auto & semi auto calibration facilities

- CEMS for Hazardous Area, optional

Analyzer Specification

- Sensor Technology

-

- Non Dispersive Infrared Absorption (NDIR),

- Zirconia (ZrO2),

- Paramagnetic,

- Ultraviolet Doppler Optical Absorption Spectroscopy (UV DOAS),

- Tuneable Diode Laser Spectroscopy (TDLS)

- Non Dispersive Ultravoilet Absorption (NDUV)

- Measurement Gas

-

-

CO: 0-5000 ppm scalable

-

NOx: 0-1000 ppm scalable

-

SO2: 0-1000 ppm scalable

-

CO2: 0-20% scalable

-

O2: 0-30% scalable

-

Cl2: 0-30 ppm scalable

-

HCl: 0-200 ppm scalable

-

HF: 0-30 ppm scalable

-

H2S: 0-200 ppm scalable

-

HC: 0-5% scalable

-

NH3: 0-500 ppm scalable

-

- Analog Output

- 4-20mA analog output

- Digital Interface

- RS 485, MODBUS Protocol

- Relay Output

- 2 Nos. relay for alarms

- Power Supply

- 110/230 VAC, 50 Hz

- Dimension

- 19” Rack

CEMS Specification

Heated Sampling Probe

-

Operating temperature: Max. 400ºC

-

Mounting: Flange type. 2”, 150# rating RF

-

Max. working pressure: 6 bar

-

Voltage: 110-230 V, 50 /60 Hz

-

Heating: Self-regulating +180ºC

-

For dust concentration: Upto 5 g/m³

-

MOC: SS 316

Heated Sample Gas Line

-

Process Tube: PTFE / SS

-

Process Tube Size: 1/4 inch OD

-

Operating Voltage: 230 V AC

-

Max. Operating Temperature: 200ºC

Sample Conditioning Unit with Industrial Cabinet

- Aspirator/Pump for sampling flue gas

- Pre and post cooler fine filters to remove drain, dust and mist in sample gas

- Auto drain and auto purging (blow back) facilities

- 2 way solenoid valves for switching, sampling, purging, draining and calibration

- Flowmeter to regulate and monitor the flow of sample gas

- Drain pump for continuous removal of condensate

- Sample Gas Cooler

- Industrial Cabinet Dimension: 1500 (H) x 600 (W) x 800 (D) mm

- Aluminium

- Cement

- Distillery

- Chlor Alkali

- Fertilizers

- Iron & steel

- Oil refinery

- Petrochemical

- Pharmaceuticals

- Power Plants

- Thermal Power Plants

- Pulp & paper

- Sugar

- Zinc

- Copper

- Boiler

- Biomedical waste Incinerator

- Common Hazardous Waste Incinerator

Related Products

Our Blog

Understanding ORP Sensors for Industrial Water Systems

Top Applications of pH Sensors in Water Treatment Plants