The Role of CEMS Analysers in Reducing Industrial Carbon Footprint

Continuous Emission Monitoring Systems (CEMS) analysers have emerged as an indispensable tool in monitoring and reducing the industrial carbon footprint. By providing real-time data on emissions, CEMS analysers allow companies to track, manage, and reduce harmful pollutants, ultimately contributing to environmental sustainability. Here, we explore the role of CEMS in reducing industrial carbon footprints.

How CEMS helps reduce carbon footprint

Accurate monitoring and reporting: The primary function of TUV certified CEMS of Bhoomi is to provide continuous, real-time data on emissions. This accurate monitoring is important for industries to understand their current carbon footprint and identify areas for improvement. The data collected can be used to create reports for regulatory compliance. But more importantly, it allows companies to set benchmarks and track progress in reducing emissions.

Process optimisation: TUV certified CEMS of Bhoomi is not just for compliance. They also play a key role in optimising industrial processes. By closely monitoring emissions, companies can identify inefficiencies in fuel usage, combustion processes or machinery operations. Optimising these processes can lead to a significant reduction in carbon emissions. For example, power plants that rely on fossil fuels can use CEMS data to fine-tune their combustion processes, ensuring that fuel is burned more efficiently. This can effectively lower CO2 emissions.

Enabling compliance with emission regulations: In many regions, strict regulations govern the emission of greenhouse gases and other pollutants. TUV certified CEMS help industries meet these regulatory requirements by providing the necessary data to demonstrate compliance. Many countries have implemented carbon trading schemes or carbon taxes, and accurate emission data is essential for industries participating in such programs. For instance, in a cap-and-trade system, industries are allocated a specific carbon allowance. If they exceed this limit, they need to purchase additional credits or pay fines. Conversely, if they emit less than their allowance, they can sell their surplus credits.

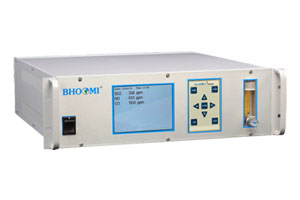

An example of CEMS technology is extractive Tunable Diode Laser Spectroscopy (TDLS) CEMS. Bhoomi’s TUV certified CEMS Tunable diode laser spectrometers (TDLS) are used in Continuous Emission Monitoring Systems (CEMS) to measure gaseous pollutants in real time. TDLS are non-contacting sensors that can perform measurements in harsh conditions, such as high temperatures, pressures, and dust concentrations. They are also isolated from the process, allowing for maintenance without taking the process offline.

Here are some features of TDLS:

- Fast response: TDLS can provide fast, accurate measurements.

- Highly specific: TDLS is highly specific to the gas being measured.

- Calibration: TDLS offers highly stable calibration.

- No sampling system needed: TDLS does not require a sampling system.

- Gas matrix interference free: TDLS is free from gas matrix interference.

- Calibration free measurement: TDLS can perform measurements without calibration.

TDLS work by emitting an infrared laser light and sweeping it over a narrow wavelength range. The laser diode analyzer then creates an average value from a large number of sweeps. The measured spectrum is compared to a known cross-section spectrum for the gas to determine the gas concentration.

However, beyond regulatory compliance, these systems play a vital role in helping companies manage and reduce their overall carbon footprint.

Looking for quality CEMS analysers?

Explore the CEMS analysers from Bhoomi. They are the only company to have multiple products in this segment. Bhoomi manufactures and supplies the analysers, which ensure top notch quality right from production to sale. Besides the stationary variants, the company also offers a portable variety of CEMS analyser, which allows for mobile operations.